Sustainable competitive advantage. It’s everything in manufacturing. Some say it is your business. Manufacturers that carve out a sustainable competitive advantage in an industry succeed. Manufacturers that don’t fail. Put another way, you either adapt or die.

Adopting this strategy is how companies become market leaders. Apple’s competitive advantage in its industry, for instance, is its reputation for innovative products. So, if you’re serious about taking your manufacturing company to the next level, you need to develop a sustainable competitive advantage.

But doing that is easier said than done. Changes in the manufacturing landscape are making it harder and harder to carve out a competitive advantage. The key is to create a clear difference between you and your competitors and that’s important to your customers.

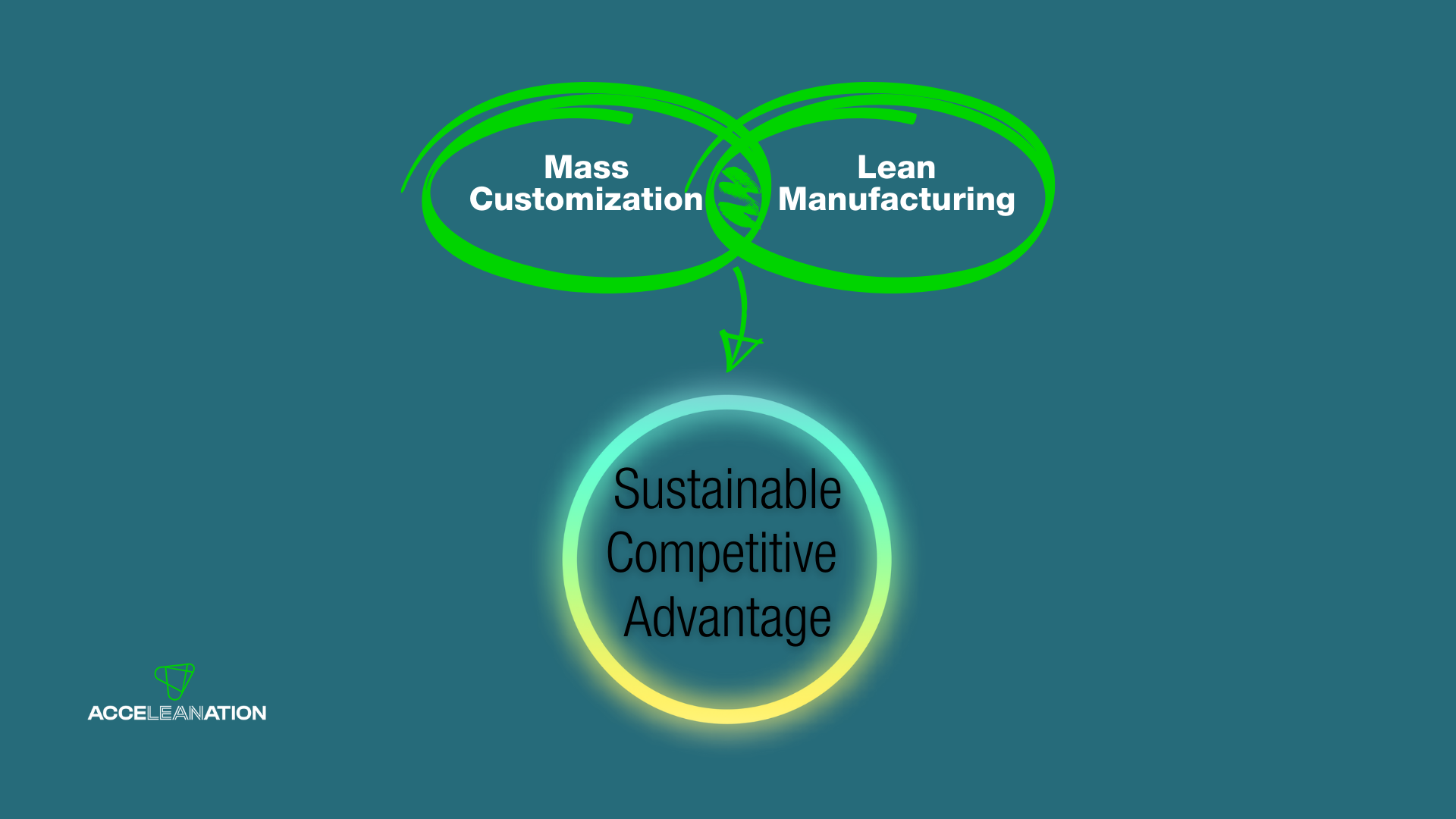

Ideally, your advantage is something others can’t match. However, strategies exist that manufacturers can use to differentiate themselves. One strategy stands out. More and more manufacturers are combining Lean manufacturing with mass customization to achieve a sustainable competitive advantage.

Lean and Mass Customization: Two Proven Approaches

Both approaches are proven. Both can boost competitiveness. And both can help generate a production approach that sets you apart. So, it makes sense to combine them. Here’s what these two approaches involve:

- Lean manufacturing requires a shift in a manufacturer’s culture and way of doing business. This shift includes changes to production methods, planning, and the way you treat employees while eliminating the inefficiencies of mass production. A Lean approach eliminates waste, reduces inventory, and improves throughput. Key building blocks of Lean include leveled production, just-in-time manufacturing, continuous flow, and stabilization and standardization of processes.

- Mass customization (MC) injects personalization into made-to-order goods. It creates products that sit somewhere between a fully personalized item and a mass-produced one. Customers don’t get completely original products with mass customization, nor do they receive fully mass-produced ones. Instead, they get goods somewhere in between. Mass customization utilizes the benefits of flexibility, integration, and personalization to produce customized products with low unit costs at near mass production efficiencies.

The key to combining these approaches is creating Lean manufacturing systems to manage mass customization. Of course, this effort will have software challenges like workflow exceptions and production bottlenecks. But an experienced implementation partner can provide practical strategies to help you deal with them.

Critical Advantages of Integrating Lean and Mass Customization

Integrating the principles and practices of these two production approaches can help generate the advantages you need to create a competitive advantage. Below are some of these strategic advantages:

1. Differentiate yourself from your competitors

This advantage is perhaps the key to this combined production strategy’s success. Differentiating yourself requires that companies do three things—distinguish product attributes along which customers’ needs, reorganize existing production processes, and help customers recognize or create solutions that meet their demands. Doing these things enables companies to distinguish themselves from their competitors both internally and externally.

2. Eliminate barriers to innovation

Innovation is a major driver of competitive advantage. But critical barriers to innovation exist for today’s manufacturers. Understanding market demand, for example, is one. Many consider it the most significant potential inhibitor to innovation in manufacturing. The difficulties manufacturers face in understanding, interpreting, and reacting to rapidly shifting marketplaces can hurt a company’s efforts to innovate successfully. Integrating Lean manufacturing and mass customization can help you eliminate these barriers and boost innovation.

3. Capitalize on economies of scale

Integrating Lean manufacturing and mass customization produces cost-advantages based on the scale of operation that comes with the cost of output decreasing with the increasing scale of production. Manufacturers can generate products in mass while minimizing costs. Costs associated with manufacturing are considered and optimized.

4. Ensure rapid delivery

The majority of a company’s production chain often remains intact—even with Lean and mass customization integration. For example, Coca-Cola still mass produces its trademark glass bottles, but it’s adapted its software and printers to generate personalized messages workers then attach to their bottles. By keeping as much of the production chain intact as possible, Coca-Cola ensures rapid delivery to its customers while minimizing costs.

5. Improved customer experience

Today’s customers are more demanding than ever. They want buying experiences tailored to their needs. Combining Lean and mass customization not only enables manufacturers to produce products more efficiently and cost-effectively. It also allows them to tailor their products specifically to customer demands. Customers can then choose the colors they like, designs, ingredients, and so on. Dell Computers exemplifies this approach.

These five advantages are just some of the advantages integrating Lean manufacturing and mass customization provides. Savvy manufacturers use these advantages to carve out a competitive edge.

Create a Long-term Competitive Advantage: Adapt or Die

No one has to tell manufacturers that it’s getting harder and harder to survive in today’s business environment. They feel the pressure daily. Factors like globalization, technological advancements, and evolving government policy are changing the manufacturing landscape.

So is the increased demand by customers for products tailored specifically for their needs. These changes have also accelerated the pace of competition. Plus, it has raised the bar for performance dramatically. The key to survival for manufacturers is creating a competitive advantage. In an environment like this, you either adapt or die.

Adapting is easier said than done. Integrating Lean manufacturing and mass customization can help. This combination makes it harder for competitors to imitate your strategy. When executed well, the combination can fashion a long-term competitive advantage that generates increased customer loyalty, higher market share, and superior profitability. If you’re not employing this strategy at your manufacturing company, the chances are good that your competitors are.

For more information on our capabilities or to schedule a free two-hour assessment session, contact us here. Put our experience and know-how to work for you.